Lowe's® Severe Weather® Treated Wood with Ecolife®

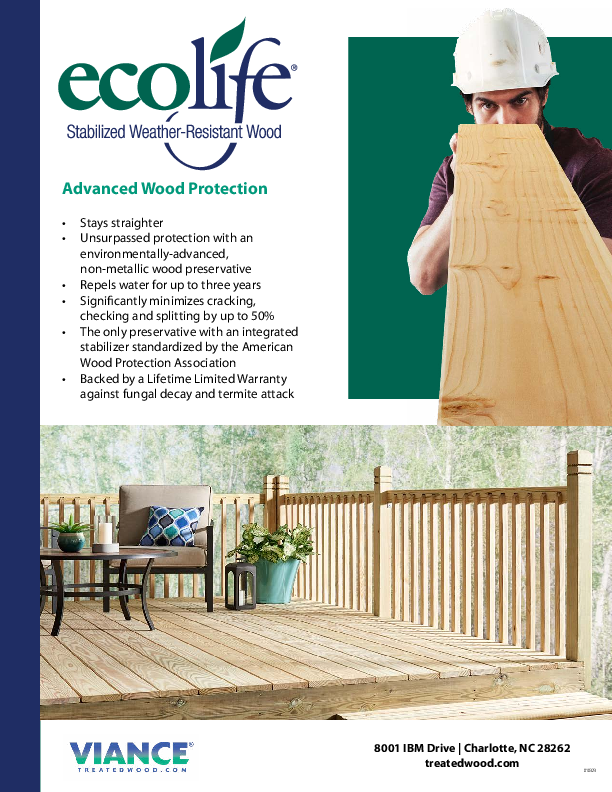

Lowe's Severe Weather treated lumber with Ecolife contains an environmentally-advanced wood protection system utilizing the only integrated wood preservative with a built-in stabilizer standardized by the American Wood Protection Association (AWPA). This proprietary system provides maximum weathering protection and enhanced performance.

The Ecolife preservative is a non-metallic preservative that fights the effects of the sun and weather extremes to repel water, minimize cracking and keep boards straighter.

Severe Weather treated wood with Ecolife is available in decking, narrow widths, decking components, and railing at Lowe's stores across the United States. Check the end tag for the AWPA "EL2" code or Ecolife logo. Lowe's and Severe Weather are registered trademarks of LF, LLC.

With Lowe's Severe Weather treated wood, you get the added benefits of Ecolife

Lowe’s® specifies Ecolife as the preservative of choice for key lumber dimensions for its Severe Weather® treated lumber brand. Ecolife is the only wood preservative system in the marketplace that contains an integrated stabilizer, delivering added value that:

- repels water

- reduces cracking

- stays straighter

Lowe’s Severe Weather treated lumber with Ecolife is used for above ground projects, six inches or more from the ground including decking, railing, joists, beams and many outdoor projects. As a part of a home’s overall design, these custom projects require the vision and craftsmanship of professional builders, who rely on consistent quality in their building materials. Their business depends on products that look good and perform without time and money wasted from culling, replacing boards, and call backs. Their projects reflect their reputation. Lowe's Ecolife treated lumber is backed by a warranty they can proudly stand behind. Since the Ecolife preservative launched in 2008, there have been virtually no claims with properly treated wood.

The active ingredient in Severe Weather treated lumber with Ecolife is DCOI. DCOI is a highly effective wood preservative and Ecolife is the only formulation with both DCOI and an integrated stabilizer standardized by the American Wood Protection Association (AWPA) for residential use. Compared to other treated products, Severe Weather with Ecolife is unsurpassed in performance and is preferred by many professional builders.

The Ecolife preservative is a nonmetal-based, environmentally advanced preservative formulation. DCOI (4,5-dichloro-2-n-octyl-4-isothiazolin-3-one), the active ingredient in Ecolife, won the US Presidential Green Chemistry Challenge Award in 1996.

Beyond Treated. Trusted.

Quick Answers to FAQs

Open All

-

What are the benefits of Ecolife® treated lumber compared to competitive wood treatments?

- The built-in wood stabilizer keeps boards straighter and minimizes cracking, checking and splitting.

- An environmentally advanced, non-metallic preservative, Ecolife (EL2) is extremely effective at .019 pcf retention, a fraction of competing products that use two times the chemicals to achieve adequate above ground product performance.

- The water repellent stabilizer is a built-in part of the preservative system and not an add-on that can vary by treater supplier.

- Fights exposure to the sun and rain and is used in building decks, railings, fence pickets, arbors, trellises, joists and beams.

- Less corrosive to connectors and fasteners and can be used in direct contact with aluminum products, even in continuously wet applications.

- Unsurpassed in effectiveness with virtually no warranty claims in its history.

- Designed for above ground applications six inches or more off the ground.

- Check where-to-buy to find a retailer near you.

-

What type of nails or screws do you recommend?

- Use code-approved hot-dipped galvanized or stainless steel corrosion-resistant fasteners and G185 hot-dipped galvanized connectors for exterior use.

- Do not mix metals. If using hot-dipped galvanized fasteners, use hot-dipped galvanized connectors. If using stainless steel fasteners, use stainless steel connectors.

- For coastal installations, use code-approved stainless steel.

-

How do I remove the grade stamp from my deck?

Light sanding will remove or lighten the grade stamp's appearance.

-

How long do I need to wait before I stain or paint my deck or fence?

- Allow treated wood to dry prior to application. Test the wood with a few drops of water to see if the wood is dry enough to readily absorb water.

- Typically, treated wood will be dry and ready for finishing 60 days after installation.

- Apply the stain to a small portion of the deck to ensure the wood is sufficiently dry.

- Follow the manufacturer's instructions.

-

What do you recommend I use to paint or stain my deck?

- Use a good quality oil-based or water-based stain, or exterior wood water sealant product with UV protection to help prevent the wood from turning gray from exposure to the sun.

- Apply a water repellent sealer at least every two years.

- Follow the manufacturer's instructions.

-

What do you recommend I use to clean my deck?

- Clean annually and keep your deck free from dirt and debris.

- A solution of liquid detergent and water with a stiff brush will remove mildew and dirt.

- For hard to clean surfaces, use a deck brightener containing oxalic acid to retain the wood’s natural beauty.

- Never use household chloride bleaches or foaming cleaners as they can strip the preservatives and damage the wood fibers leaving an unnatural whitewashed appearance.

- Be careful if using a pressure-washer as excessive pressure may cause damage to the wood.

-

Any tips on installation?

- For exterior project applications, treat all field-cut ends of boards and drilled holes with a brush-on wood preservative. Copper naphthenate formulations are available from home centers, lumber dealers and hardware stores. Deck stains and sealers do not provide adequate protection.

- Butt boards tightly together during installation as they will shrink slightly in width and thickness as they dry out.

- Pre-drill holes at the ends of boards, no closer than 1/2" from board ends or sides, to help prevent splitting.

- Use screws to improve holding performance.

- Install fasteners flush to the wood surface. Do not overdrive fastener.

- Install the un-cut end of support posts in ground contact applications.

-

What safe practices should I use when working with treated wood?

- Wear gloves, goggles and dust mask when working with treated wood.

- Wash hands thoroughly with mild soap and water after working with treated wood.

- Do not burn or use treated wood debris as mulch.

- Do not use treated wood where it may come into direct or indirect contact with drinking water or a component of food, animal feed or beehives.

- Dispose of treated wood debris in accordance with local regulations.

-

How do I get rid of mold on my deck?

Mold that you find on pressure treated wood is not an indication of a fungal attack. Mold can grow on the surface of many products including wood (treated and untreated) due to exposure to moisture. To remove mold from your treated deck, use mild soap and water solution and a stiff brush.

Mold Growth

Mold and mildew are present everywhere in our environment, both indoors and outdoors. Mold and mildew need four things to thrive: air, water, temperatures between 32 and 120°F, and a food source, conditions that are common wherever humans live, work, and play.

The best way to minimize mold and mildew growth is to control water and food sources. When it comes to mold or mildew on wood decking, water and organic matter are the primary conditions that enable mold and mildew colonies to thrive. To minimize these conditions, make sure water has the ability to flow away from the deck surface and areas surrounding the deck to lessen the absorption of water. Ensure there is adequate ventilation between deck boards and underneath the deck surface, so water can rapidly evaporate.

And since both mold and mildew feed on dead or decaying organic matter, so it is important to keep your deck clean of leaves and debris.

Cleaning Your Deck

To minimize mold on your decking, clean your deck as often as needed, at least twice each year. Climate conditions vary in different regions of the country and may necessitate more periodic cleaning.

Remove leaves, debris, and other organic materials that provide a food source for mold.

If mold is present, there are many commercial products available for cleaning mold. We recommend commercial cleaners containing oxalic acid. For best results, follow the manufacturer’s instructions and use cleaners within their stated shelf life. Do not mix recommended cleaning products together as harmful chemical reactions could occur.

We do not recommend household chloride bleaches or foaming cleaners as they can strip the preservatives and damage the wood fibers leaving an unnatural whitewashed appearance.

To maximize application coverage, remove excessive organic growth or clumps prior to applying the cleaner.

Coatings for High Mold-Prone Environments

For environments prone to high mold growth, there are commercially available coatings and finishes that seal the wood surface when applied and they should be maintained per the manufacturer’s instructions.

- Coatings should be applied within one week of cleaning for best results.

- Prior to coating, properly clean the decking, rinse thoroughly with water and allow to dry completely.

- Sweep off any pollen and debris.

Tips for Minimizing Mold

- Maintain a deck that is dry and clean.

- Ensure gutters / down-spouts and dryer vents do not discharge directly on decks.

- Ensure adequate ventilation under and between decking boards.

- Minimize water puddles under decks and the use of wet mulch up against the deck structure.

- Cleaning a deck just after the last of the major pollen events (when your car doesn't change color from the pollen anymore) will minimize the seasonal outbreak of mold and mildew.

- Periodically rinse off your deck using a garden hose with a spray nozzle, especially after the major pollen events. Skilled professionals may use pressure washers with wide fan tips but in the wrong hands, your deck can be damaged. Exercise extreme caution when using pressure washers.

- Ensure the gaps between the decking boards remain free of debris so that regular rain showers can remove pollen and organic debris between cleanings.

- Avoid fertilizer over-spray.

Product Applications

Outdoor Projects Six Inches or More from the Ground

-

Severe Weather with Ecolife treated wood decking is ideal for residential use for decking, deck framing, railing, joists and beams.

-

Severe Weather with Ecolife is perfect for porches, arbors, gazebos, trellis', and walkways.

-

Also used in homeowner projects, Severe Weather treated wood is used to build picnic tables, outdoor furniture, benches and playsets.

-

For commercial agriculture use, Severe Weather treated wood is used for boardwalks, decks, wood framing for outdoor structures, bridges, sill plates and furring strips.

The Qualities That Matter to You

- No need to seal for up to two years due to built-in water repellency

- Significantly minimizes cracking, checking and splitting by up to 50%

- Keeps boards straighter for long-term beauty

- Less corrosive to fasteners and compatible with aluminum products

- Lifetime Limited Warranty* protects the long-term performance of your project

Severe Weather treated lumber with Ecolife offers a Lifetime Limited Warranty* against damage from fungal decay or termite attack when installed in accordance with applicable building codes. Warranty coverage includes above ground use, six inches or more from the ground, which includes above ground joists, beams and framing members that are critical to the safety and performance of the structure. *See Ecolife Lifetime Limited Warranty for terms and conditions.

Green Certified Product

Ecolife is a non-metallic preservative and is an Home Innovation Research Labs NGBS Green Certified Product for Resource Efficiency. This means Severe Weather treated lumber with Ecolife is eligible to contribute points toward a building's certification under the National Green Building Standard™ (NGBS).

Ecolife is an American Wood Protection Association standard as a complete wood protection system, combining fungicides and biocides to protect and stabilize wood for above ground applications for residential and certain agricultural uses, six inches or more from the ground. Ecolife treated wood is used in the following uses or components in these popular projects:

- decking, deck framing, joists, and beams

- porches, arbors, gazebos, trellis’, and walkways

- picnic tables, outdoor furniture, benches and playsets

- commercial boardwalks, outdoor structures and bridges

- sill plates and furring strips

Pro-preferred, Ecolife gives Severe Weather added advantages that ordinary treated lumber does not offer. Professional deck builders receive these benefits with Ecolife:

- Minimize lost time and money spent on culling, complaints and callbacks

- Offer quality aesthetics and a high-performing natural, wood option

- Differentiates their products from the competition

- Can offer premium exterior wood products and deck packages for their customers

Homeowners receive these advantages:

- No water repellent needed for up to 2-3 years, reducing initial maintenance

- Less surface cracking and checking

- Wood decks are more economical and retain more value than all other decking options

- Can be finished to match any color scheme

- Real wood decks offer natural beauty

- Backed by a lifetime limited warranty

Ecolife/Severe Weather Product Information

Ecolife CSI 3-part Architectural Specs

SDS Ecolife EL2 Pressure Treated Wood

How to Specify Treated Wood Products

IBC and IRC Building Code Compliant, Ecolife Stabilized Weather-Resistant Wood is AWPA standardized and building-code approved (Use Categories U1, UC3B) for above-ground applications such as decks, fencing, wood framing and similar projects. (Not intended for contact with soil).

The AWPA Standards are the only treated wood standards directly referenced in the IBC and IRC. Look for “AWPA U1” on the end tags of all treated lumber used for exterior projects.

The Prescriptive Residential Deck Construction Guide includes guidance compiled by the American Wood Council (AWC) on provisions of the International Residential Code (IRC) pertaining to single level residential wood deck construction. To ensure that you always have the latest version of the document, please check their website.